Working cleanly and safely

In structural steel engineering, metal needs to be cut and ground as a continuous process – whether to build factory buildings, fencing, bridgework or for larger-scale infrastructure work such as electricity pylon construction.

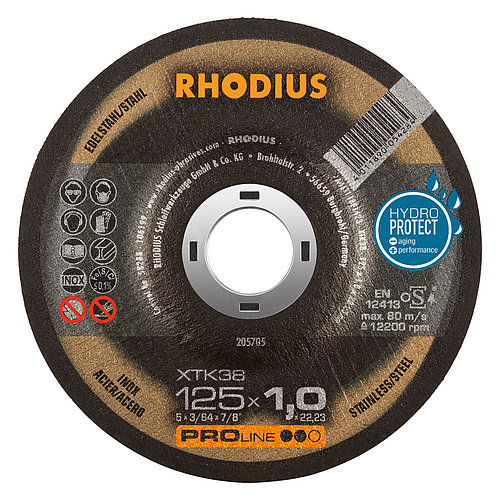

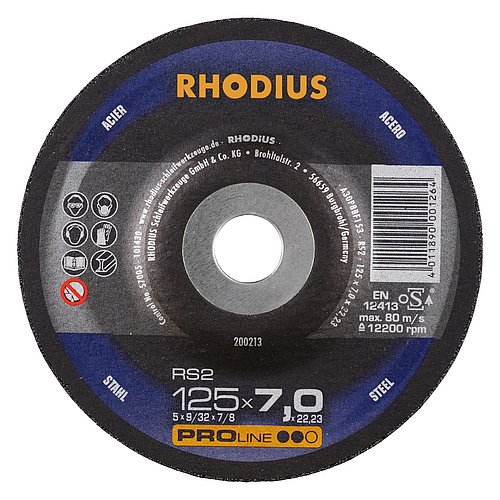

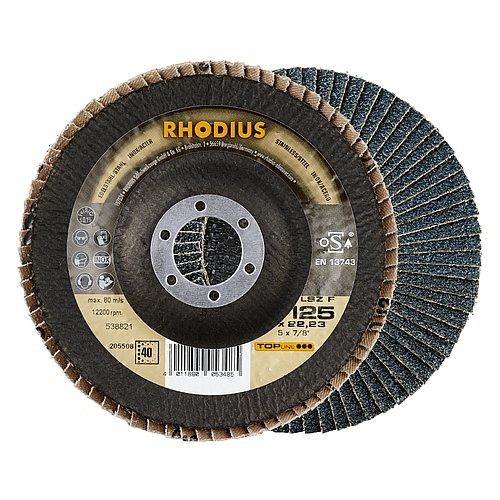

This usually involves working with carbon steel. A wide variety of machinery is used for these applications – from angle grinders to chop saws. The grinding tool or cutting disc used here must naturally be perfectly matched to both the machine and to the respective application. This is not an area where a ‘one-size-fits-all’ disc will work. To ensure it meets this wide range of requirements, RHODIUS has deliberately created a broad-based portfolio featuring a range of different high-quality product lines.