Carbide burr, shape H (FLF): flame. • High concentricity • Optimal cutting geometry ensures best work results • Long lifetime Machine suitability: The HF H Z7 tungsten carbide burr can be used with straight grinders, flexible shaft drive machines and air grinders. The recommended cutting speed is 450–600 m/min for unalloyed steels/cast steels/cast iron, and 250–350 m/min for alloyed steels/tool steels/rust- and acid-proofed steels. Structure and production: The head is attached using a specialised brazing technique, while the teeth are cut using high-precision diamond discs on advanced CNC machines. This technique ensures an optimum and high-performance cutting geometry. Applications: This carbide burr as a double cut variant with chip breaker offers users a long tool life as well as high concentricity at a low price. Dimensions: The carbide burr with shape H (flame) according to DIN 8032 is available with a head diameter of 12.7 mm. The shank diameter is 6 mm.

Stainless steel

Stainless steel

Steel

Steel

Cast iron

Cast iron

Carbide burr, shape M (SKM): cone. • High concentricity • Optimal cutting geometry ensures best work results • Long lifetime Machine suitability: The HF M Z7 tungsten carbide burr can be used with straight grinders, flexible shaft drive machines and air grinders. The recommended cutting speed is 450–600 m/min for unalloyed steels/cast steels/cast iron, and 250–350 m/min for alloyed steels/tool steels/rust- and acid-proofed steels. Structure and production: The head is attached using a specialised brazing technique, while the teeth are cut using high-precision diamond discs on advanced CNC machines. This technique ensures an optimum and high-performance cutting geometry. Applications: This carbide burr as a double cut variant with chip breaker offers users a long tool life as well as high concentricity at a low price. Dimensions: The carbide burr with shape M (cone) according to DIN 8032 is available with head diameters of 9.6 mm and 12.7 mm. The shank diameter is 6 mm.

Stainless steel

Stainless steel

Steel

Steel

Cast iron

Cast iron

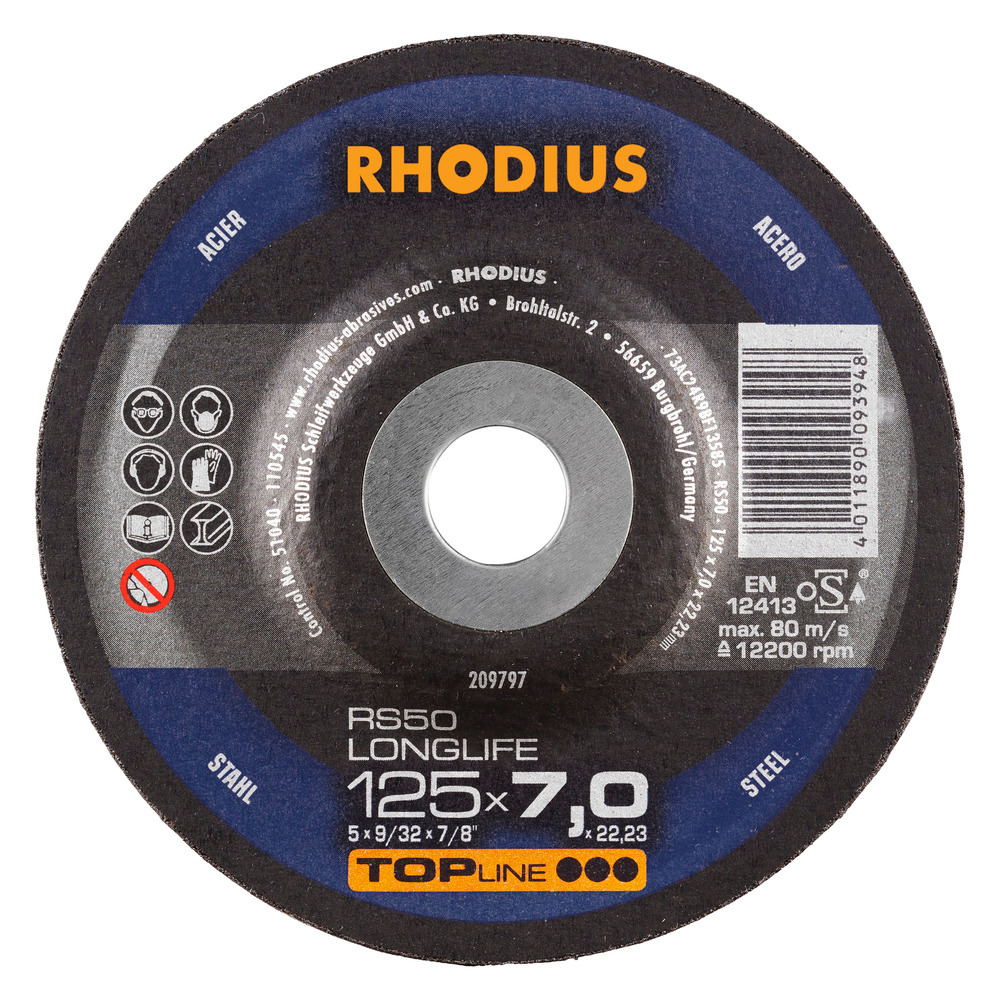

High-performance grinding disc with high bond strength for a long lifetime and powerful material abrasion. • Ideal for powerful work on steel and cast-iron • Additional fabric flange from 180 mm diameter for use on high-frequency and compressed-air angle grinders • Safe thanks to three full-face fabric layers Machine suitability: The RHODIUS RS50 FUSION is a grinding disc (shape 27) for angle grinders in any performance class. This product really shines when used on high-performance machines in particular. Material suitability: The RHODIUS RS50 LONGLIFE has been specifically designed for processing steel (carbon steel – also termed structural steel, St37, S235JR or 1.0037) and cast steel. The RS50 LONGLIFE grinding disc is an excellent choice for chamfering, welding seam preparation, for finishing work on welding seams, for fettling or smoothing cast parts, as well as for deburring work and rounding off edges. This tool is also suitable for surface grinding work. Structure and production: The disc is manufactured to EN 12413, safety-tested and certified to oSa standards. Every thousandth disc undergoes safety testing at almost double the normal working speed. The product features high-quality abrasive grain (aluminium oxide/corundum) and a matching phenol resin formulation, and is reinforced by three full-coverage glass cloth layers. This grinding disc therefore comfortably exceeds the side load criterion of 290 N required by safety regulations. Quality: With the RS50 LONGLIFE, users get the best RHODIUS tool in its category. RHODIUS TOPline products represent a maximum level of performance and quality. Applications: The RS50 LONGLIFE offers an impressive and aggressive level of stock removal performance combined with a long lifetime. Thanks to its topcoat of fine grain, this disc keeps chipping to a minimum. Dimensions: The RS50 LONGLIFE grinding disc has a disc width of 7.0 mm, and is available in diameters from 115 mm to 230 mm. Industries: This grinding disc is the preferred choice for tasks in metalwork shops, in steelwork and shipyards, and in tank, plant and pipeline construction.

Steel

Steel

Cast iron

Cast iron

Grinding disc with extra fabric flange for use on high-frequency or compressed-air angle grinders, offering superior stock removal, good service life. • Especially safe through additional fabric • High stock removal performance • Good lifetime Machine suitability: The RHODIUS RS22 is a grinding disc (shape 27) for angle grinders in any performance class, including high-frequency (HF) machines and air grinders. Material suitability: The RHODIUS RS22 has been specifically designed for processing steel (carbon steel – also termed structural steel, St37, S235JR or 1.0037) and cast steel. The RS22 grinding disc is an excellent choice for chamfering, welding seam preparation, for finishing work on welding seams, for fettling or smoothing cast parts, as well as for deburring work and rounding off edges. This tool is also suitable for surface grinding work. Structure and production: The disc is manufactured to EN 12413, safety-tested and certified to oSa standards. Every thousandth disc undergoes safety testing at almost double the normal working speed. The product features a high-quality ceramic grain and a matching phenol resin formulation, and is reinforced by three full-coverage glass cloth layers plus an extra, smaller flange cloth. This grinding disc therefore comfortably exceeds the side load criterion of 290 N required by safety regulations. Quality: The RS22 gives users a tool that easily meets the demanding requirements for quality in manufacturing and the skilled trades. To help make work even more cost-effective, RHODIUS grinding discs from the premium TOP line are recommended. Applications: The RS22 offers users an impressively long lifetime. As a result of its topcoat of fine grain, this disc keeps chipping to a minimum. Dimensions: The RS22 grinding disc has a disc width of 8.0 mm, and is available in diameters from 180 mm to 230 mm. Industries: This grinding disc is the preferred choice for tasks in steelwork and in pipeline construction.

Steel

Steel

Cast iron

Cast iron

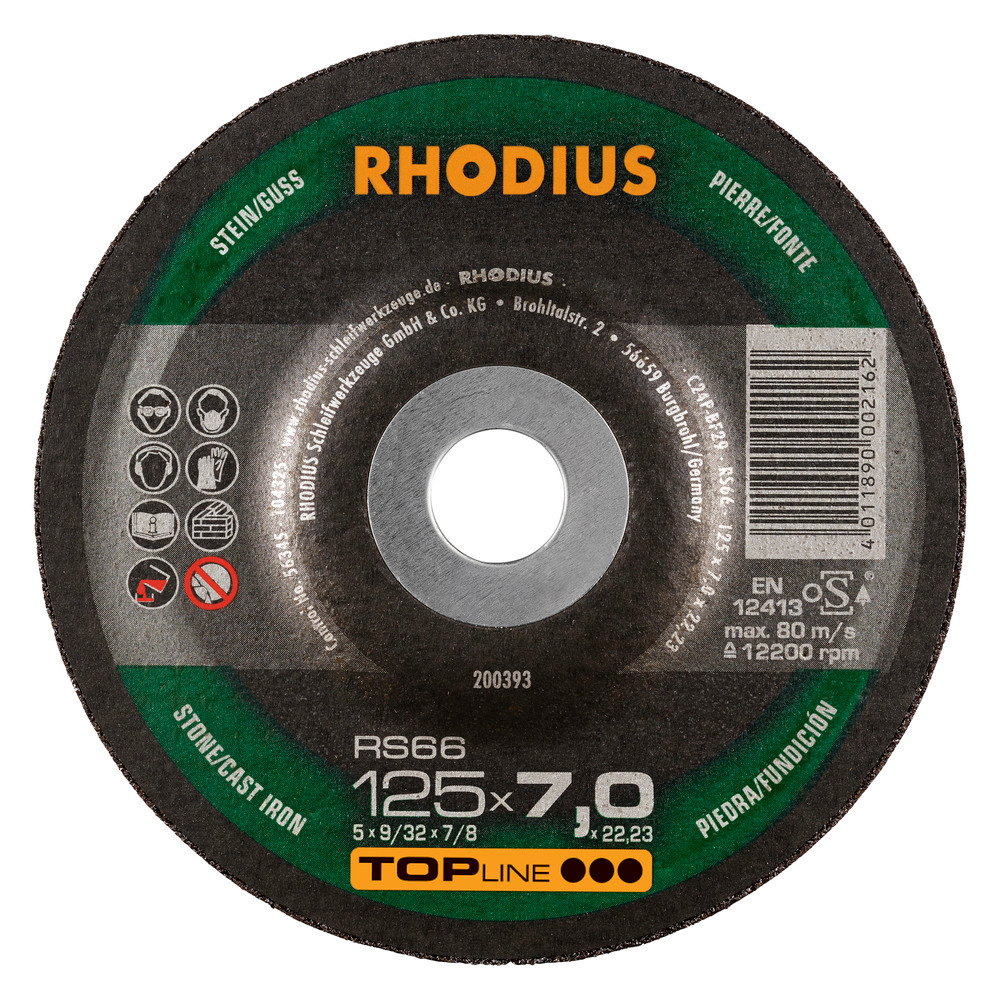

Grinding disc for stone and also processing of grey cast iron and titanium. • Long service life • Good stock removal performance • Aggressive grinding Machine suitability: The RHODIUS RS66 FUSION is a grinding disc (shape 27) for angle grinders in any performance class. Material suitability: The RHODIUS RS66 has been developed specially for processing cast titanium, and for work on hard or abrasive stone. The RS66 grinding disc is an excellent choice for fettling or smoothing cast parts and for rounding off edges. Structure and production: The disc is manufactured to EN 12413, safety-tested and certified to oSa standards. Every thousandth disc undergoes safety testing at almost double the normal working speed. The product features high-quality abrasive grain (silicon carbide) and a matching phenol resin formulation, and is reinforced by three full-coverage glass cloth layers. This grinding disc therefore comfortably exceeds the side load criterion of 290 N required by safety regulations. Quality: With the RS66, users get the best RHODIUS tool in its category. RHODIUS TOPline products represent a maximum level of performance and quality. Applications: The RS66 offers users an impressively long lifetime. Dimensions: The RS66 grinding disc has a disc width of 7.0 mm, and is available in diameters from 115 mm to 230 mm. Industries: This grinding disc is the preferred choice for processing work on stone.

Stone

Stone

Cast iron

Cast iron

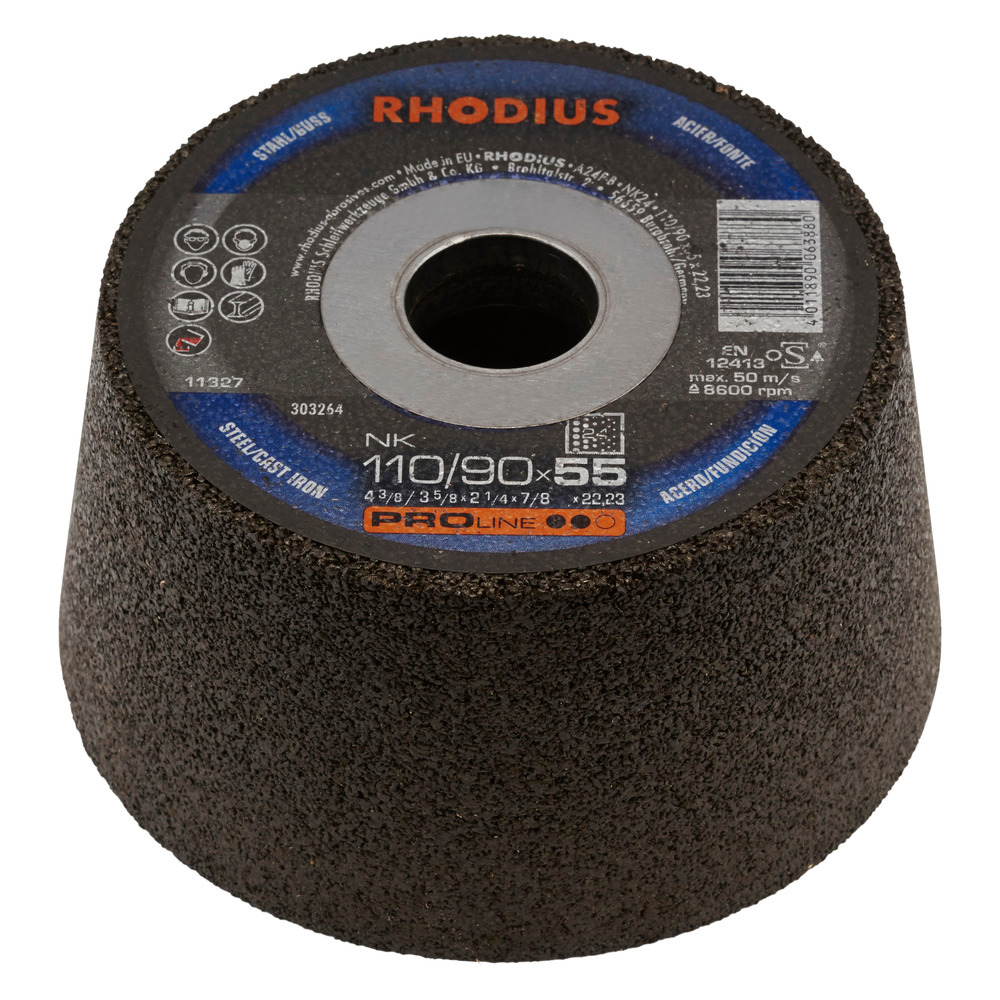

Cup wheel for grinding work on surfaces and edges in steel work, and when processing welding seams. • High stock removal performance • Long service life Machine suitability: The RHODIUS NK is a cup wheel (shape 11) for angle grinders. The cup wheel must always be used with its special matching protective hood. Material suitability: The tool has been specifically designed for processing steel (carbon steel – also termed structural steel, St37, S235JR or 1.0037) and cast steel. This cup wheel is an excellent choice for chamfering, welding seam preparation, for finishing work on welding seams, as well as for deburring work and rounding off edges. Structure and production: The cup wheel is manufactured to EN 12413, safety-tested and certified to oSa standards. The product features high-quality abrasive grain (aluminium oxide/corundum) and a matching phenol resin formulation. Quality: The NK cup wheel gives users a tool that easily meets the demanding requirements for quality in manufacturing and the skilled trades. Applications: The NK offers impressively high stock removal performance with a long lifetime. Dimensions: The NK cup wheel is available with a diameter of 110/90 mm. Industries: This cup wheel is the preferred choice for steelwork and work in shipyards.

Steel

Steel

Cast iron

Cast iron

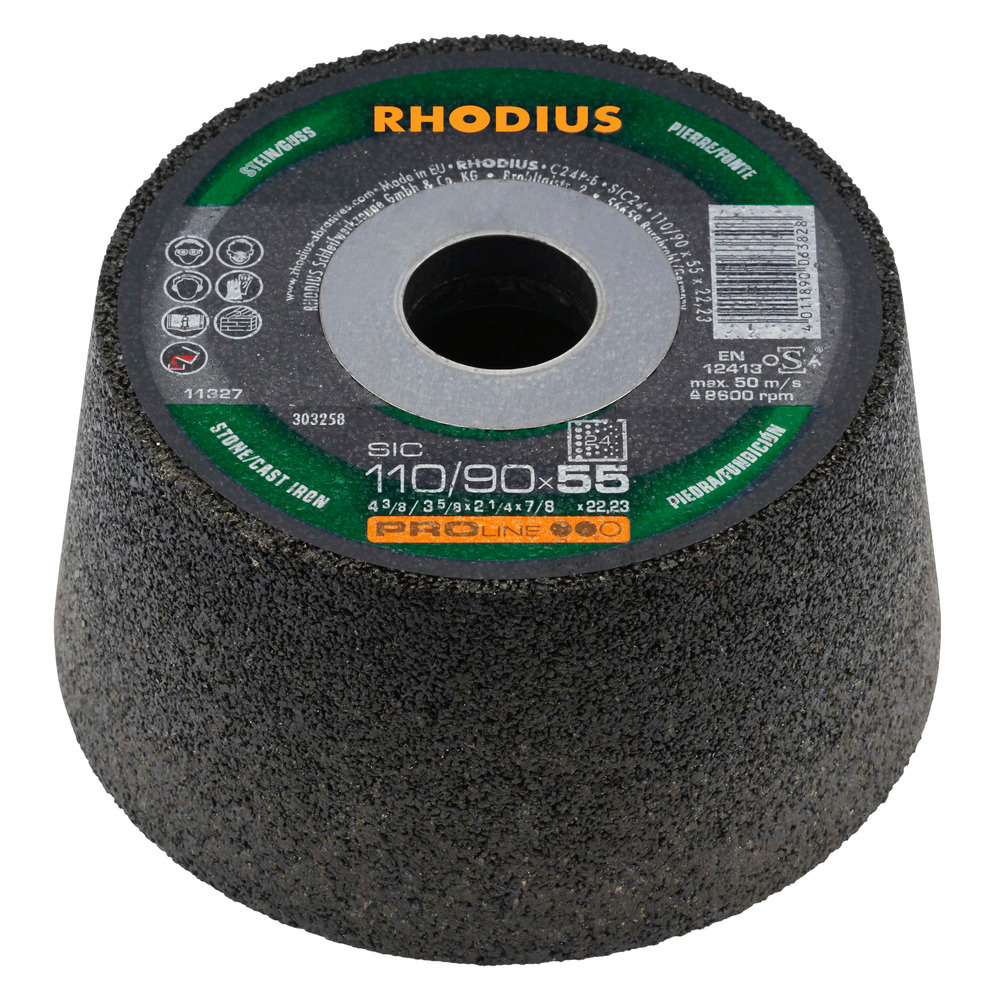

Cup wheel for use in grinding work on stone surfaces and edges. • High stock removal performance • Long service life Machine suitability: The RHODIUS SIC is a cup wheel (shape 11) for angle grinders. The cup wheel must always be used with its special matching protective hood. Material suitability: The tool has been specifically developed for processing cast titanium, and for work on hard or abrasive stone. This cup wheel is an excellent choice for chamfering, for fettling cast parts and for smoothing off edges. Structure and production: The cup wheel is manufactured to EN 12413, safety-tested and certified to oSa standards. The product features high-quality abrasive grain (silicon carbide) and a matching phenol resin formulation. Quality: The SIC cup wheel gives users a tool that easily meets the demanding requirements for quality in manufacturing and the skilled trades. Applications: The SIC offers impressively high stock removal performance with a long lifetime. Dimensions: The SIC cup wheel is available with a diameter of 110/90 mm. Industries: This cup wheel is the preferred choice for processing work on stone.

Stone

Stone

Cast iron

Cast iron

Stationary cutting disc with high stock removal performance. Extra exterior reinforcement for use at high working speeds. • High cutting speed • Suitable also for cast-iron parts Machine suitability: The ST56 cutting disc can be used on stationary chop saw and table saw machines. Material suitability: The ST56 is designed especially for use on steel (carbon steel – also termed structural steel, St37, S235JR and 1.0037) and cast steels (ductile or grey cast iron, etc.). Structure and production: The cutting disc contains high-quality corundum (aluminium oxide) and 2 full-coverage glass cloth layers. The minimum side load for the cutting disc as defined by EN 12413 and oSa is 40 N (50 N from a diameter of 150 mm). The expiry date (three years) is embossed in the disc hole ring. Consistently high quality is ensured by sophisticated in-process controls applied during manufacturing. To ensure a maximum level of safety, every thousandth disc is tested destructively. This disc features a straight shape (shape 41). Cutting discs with a straight shape enable deeper insertion depths and therefore a greater number of cuts. Quality: The ST56 gives users a tool that easily meets the demanding requirements for quality in manufacturing and the skilled trades. Applications: The ST56 offers an impressively aggressive cut during use, plus smooth, vibration-free operation. This cutting disc helps to make work especially cost-effective. This high-quality RHODIUS tool is especially suitable for cutting high-alloy steel as well as high-strength sheet metal, supports, sections and beams. Dimensions: With a disc width of 3.0 mm to 5.0 mm, this stationary cutting disc is available in diameters from 300 mm to 500 mm. Industries: The disc is the ideal tool for tackling the wide range of applications and challenges faced by building fitters, as well as in plant or container construction, in foundries and fettling shops, boiler and tank construction, and structural steel engineering.

Steel

Steel

Cast iron

Cast iron

Heavy-duty stationary cutting disc with rugged exterior reinforcement for safe cutting. • Long lifetime • Cool cut • Easy cutting Machine suitability: The ST21 cutting disc can be used with stationary machines. Material suitability: The ST21 is specially designed for use on steel (carbon steel – also termed structural steel, St37, S235JR and 1.0037) and cast steels (ductile or grey cast iron, etc.). Structure and production: The cutting disc contains high-quality corundum (aluminium oxide) and 2 full-coverage glass cloth layers. The minimum side load for the cutting disc as defined by EN 12413 and oSa is 40 N (50 N from a diameter of 150 mm). The expiry date (three years) is embossed in the disc hole ring. Consistently high quality is ensured by sophisticated in-process controls applied during manufacturing. To ensure a maximum level of safety, every thousandth disc is tested destructively. This disc features a straight shape (shape 41). Cutting discs with a straight shape enable deeper insertion depths and therefore a greater number of cuts. Applications: During use, the ST21 offers a highly aggressive cut, as well as a long lifetime, a low level of sparking and smooth, vibration-free operation. This cutting disc helps to make work especially cost-effective. This high-quality RHODIUS tool is especially suited to cutting structural and tool steel, spring steels and high-alloy steel, as well as high-strength sheet metal, supports and sections. Dimensions: The stationary cutting disc is available with a disc width of 3.0 mm to 4.0 mm, in diameters from 300 mm to 400 mm. Industries: This is the ideal tool for the many applications and challenges faced in plant or container construction, in foundries and fettling shops, boiler and tank construction, structural steel engineering and pipeline construction.

Steel

Steel

Cast iron

Cast iron

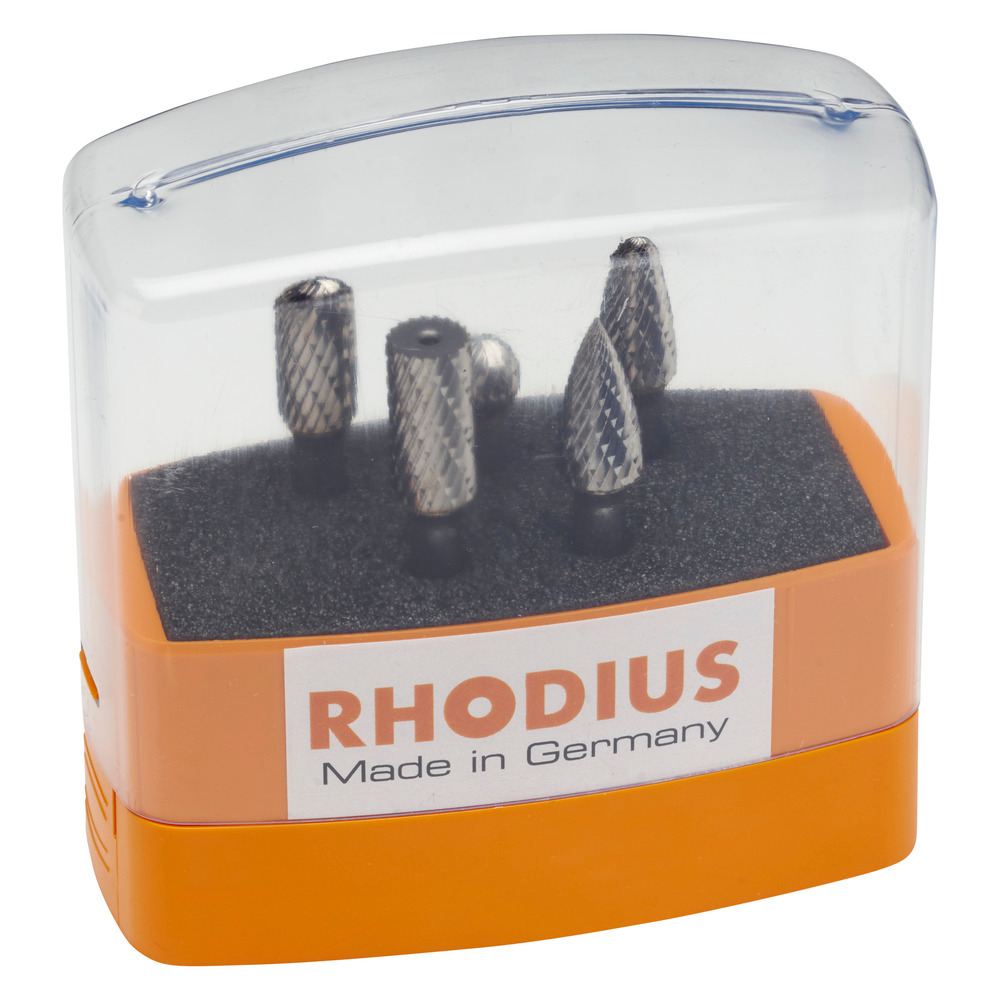

Carbide burr set, consisting of the three/five most popular carbide burr shapes. • Double cut for high material abrasion • Attractive plastic box for easy storage Machine suitability: <p>The tungsten carbide burrs can be used with straight grinders, flexible shaft drive machines and air grinders. The recommended cutting speed is 450–600 m/min for unalloyed steels/cast steels/cast iron, and 250–350 m/min for alloyed steels/tool steels/rust- and acid-proofed steels.</p> Structure and production: <p>The head is attached using a specialised brazing technique, while the teeth are cut using high-precision diamond discs on advanced CNC machines. This technique ensures an optimum and high-performance cutting geometry. The double cut variant ensures very high material abrasion.The tungsten carbide burrs can be stowed away safely in the handy plastic box.</p> Quality: <p>The HF SET provides users with the best RHODIUS tools in their category. RHODIUS TOPline products represent a maximum level of performance and quality.</p> Applications: <p>The tungsten carbide burrs offer an impressive level of concentricity. These tools can be guided easily even for less aggressive stock removal work. High-precision milling is easy for users to achieve. Thanks to their very sturdy tooth design, the burrs also offer users a long tool life.</p> Dimensions: <p>This set of tungsten carbide burrs includes the three/five most popular carbide burr shapes:ball-nosed cylinder, ball and ball-nosed tree or cylinder without end cut, ball-nosed cylinder, ball, ball-nosed tree, tree. The head diameter is 9.7 mm in each case.</p>

Stainless steel

Stainless steel

Steel

Steel

Cast iron

Cast iron