Non-woven cleaning abrasive with high-performance ceramic abrasive grain. For powerful cleaning performance and an extremely long lifetime. • Stable edges • Top cleaning performance • With high-performance ceramic abrasive grains Machine suitability: The SVS HD non-woven cleaning abrasive is designed for use on an angle grinder with a 22.23 mm spindle. An adjustable-speed angle grinder must be used with this product. The non-woven material will melt if the speed is too high. The optimum speed range is from 3,000 to 7,000 rpm. Material suitability: This product is the ideal choice for removing rust or paint, and has been specially designed for processing stainless steel (SST, Inox), e.g. 1.4031 (X5CrNi18-10 or 304), steel (carbon steel – also termed structural steel, St37, S235JR and 1.0037) and cast steels, as well as aluminium and other non-ferrous metals such as copper, brass and bronze, etc. The product achieves good to very good results when used on any of the materials listed here. The product can also be used to remove GFRP and body filler as well as for working on wood. Structure and production: This non-woven cleaning abrasive is made from high-performance ceramic abrasive grain and has very high edge strength. With this tool, the user benefits from a long tool lifetime and superior cleaning performance. The open design prevents clogging, while the high grit concentration yields excellent results when tackling rust and paint. Quality: With the SVS HD, users get the best RHODIUS tool in its category. RHODIUS TOPline products represent a maximum level of performance and quality. Applications: The SVS HD remains the tool of choice even for cleaning high-strength steels, metal sheets, structural and tool steels. Dimensions: The non-woven abrasive disc is available in the diameters of 115 mm and 125 mm. Industries: The RHODIUS SVS HD non-woven abrasive disc is the ideal tool for the many applications and challenges faced in car repair and metalwork shops, in plant and container construction, boiler and tank construction, structural steel engineering, pipeline construction and installation work.

Stainless steel

Stainless steel

Steel

Steel

Non-ferrous metals

Non-ferrous metals

Paints/fillers

Paints/fillers

Non-woven cleaning tool for the quick change system with ceramic high-performance abrasive grain. • Stable edges • Maximum cleaning performance • Quick tool change without bonding or sliding Machine suitability: A backing pad is required when using the RHODIUS SVS QUICK HD non-woven quick change cleaning disc. The quick change disc is mounted onto the backing pad in a matter of seconds. This adapter makes it possible to use the product easily on a machine with a flexible shaft drive (with angled hand piece and 6 mm spindle). The product must be used only on adjustable-speed machines and at a reduced speed. The non-woven material will melt if the speed is too high. Material suitability: This quick change disc has been designed especially for processing stainless steel (SST, Inox), e.g. 1.4031 (X5CrNi18-10 or 304), steel (carbon steel – also termed structural steel, St37, S235JR or 1.0037) and cast steel. Users will also achieve very good results with the SVS QUICK HD when working on wood, paint and filler. Structure and production: The non-woven cleaning disc for the quick change system utilises self-sharpening high-performance ceramic abrasive grain that provides an impressive level of cleaning performance. At the same time, the SVS QUICK HD has very high edge strength. Quality: With the RHODIUS SVS QUICK HD quick change disc, users get the best RHODIUS tool in its category. RHODIUS TOPline products represent a maximum level of performance and quality. Applications: This tool is an excellent choice for high-precision grinding work, and especially where this involves very small spaces or hard-to-reach areas. The quick change system permits rapid tool changeover without sticking or slippage. Dimensions: The SVS QUICK HD is available in the diameters of 51 mm and 76 mm, and with an extra coarse grit. Industries: A RHODIUS quick change disc is the perfect tool for tackling the many kinds of applications and challenges found in car repair and servicing shops, in metalwork shops, in plant and tank construction, and for general installation work. These tools make work easier by offering first-class performance on rustproof and acid-proofed steels, on high-strength and high-alloy steels, and on tempered steels and high-strength metal sheets.

Steel

Steel

Stainless steel

Stainless steel

Wood

Wood

Paints/fillers

Paints/fillers

Non-woven tool for the quick change system. For fine grinding work. • Uniform surface finish • High proportion of grain binder for long lifetime • Quick tool change without bonding or sliding Machine suitability: A backing pad is required when using the RHODIUS VLS QUICK quick change mini non-woven disc. The quick change disc is mounted onto the backing pad in a matter of seconds. This adapter makes it possible to use the product easily on a machine with a flexible shaft drive (with angled hand piece and 6 mm spindle). The product must be used only on adjustable-speed machines and at a reduced speed. The non-woven material will melt if the speed is too high. Material suitability: This quick change disc has been designed especially for processing stainless steel (SST, Inox), e.g. 1.4031 (X5CrNi18-10 or 304) and steel (carbon steel – structural steel, St37, S235JR and 1.0037) and cast steels, as well as aluminium and other non-ferrous metals such as copper, brass and bronze, etc. Users will also achieve very good results with the VLS QUICK when working on paint and filler. Structure and production: The non-woven disc for the quick change system is especially well-suited to fine grinding and pre-polishing work. The high proportion of grain binder used with this non-woven disc ensures a particularly long lifetime. Quality: The RHODIUS VLS QUICK quick change disc gives users a tool that easily meets the demanding requirements for quality in manufacturing and the skilled trades. To help make work even more cost-effective, RHODIUS quick change discs from the premium TOP line are recommended. Applications: This tool is an excellent choice for jobs that require a very even surface finish or pre-polishing finish. The quick change system permits rapid tool changeover without sticking or slippage. Dimensions: The VLS QUICK is available in the diameters of 51 mm and 76 mm. To ensure an optimum working result and surface finish at all times, the user can select from several grit variants: coarse/100, medium/180 and fine/280. Industries: A RHODIUS quick change disc is the perfect tool for tackling the many kinds of applications and challenges found in car repair and servicing shops, in metalwork shops, in plant and tank construction, and for general installation work. These tools make work easier by offering first-class performance on rustproof and acid-proofed steels, on high-strength and high-alloy steels, and on tempered steels and high-strength metal sheets.

Stainless steel

Stainless steel

Steel

Steel

Non-ferrous metals

Non-ferrous metals

Paints/fillers

Paints/fillers

Non-woven tool for the quick change system. For fine grinding work. • Uniform surface finish • High proportion of grain binder for long lifetime • Quick tool change without bonding or sliding Machine suitability: A backing pad is required when using the RHODIUS VLS QUICK HD quick change mini non-woven disc. The quick change disc is mounted onto the backing pad in a matter of seconds. This adapter makes it possible to use the product easily on a machine with a flexible shaft drive (with angled hand piece and 6 mm spindle). The product must be used only on adjustable-speed machines and at a reduced speed. The non-woven material will melt if the speed is too high. Material suitability: This quick change disc has been designed especially for processing stainless steel (SST, Inox), e.g. 1.4031 (X5CrNi18-10 or 304) and steel (carbon steel – structural steel, St37, S235JR and 1.0037) and cast steels, as well as aluminium and other non-ferrous metals such as copper, brass and bronze, etc. Users will also achieve very good results with the VLS QUICK HD when working on paint and filler. Structure and production: The non-woven disc for the quick change system is especially well-suited to fine grinding and pre-polishing work. The high proportion of grain binder plus the self-sharpening, ceramic high-performance abrasive grain used with this non-woven disc ensures a particularly long tool lifetime. Quality: The RHODIUS VLS QUICK HD quick change disc gives users a tool that easily meets the demanding requirements for quality in manufacturing and the skilled trades. To help make work even more cost-effective, RHODIUS quick change discs from the premium TOP line are recommended. Applications: This tool is an excellent choice for jobs that require a very even surface finish. The quick change system permits rapid tool changeover without sticking or slippage. Dimensions: The VLS QUICK HD is available with a diameter of 51 mm. To ensure an optimum working result and surface finish, the user can choose from the grit variants of coarse/HD (K50) or medium/HD (K80). Industries: A RHODIUS quick change disc is the perfect tool for tackling the many kinds of applications and challenges found in car repair and servicing shops, in metalwork shops, in plant and tank construction, and for general installation work. These tools make work easier by offering first-class performance on rustproof and acid-proofed steels, on high-strength and high-alloy steels, and on tempered steels and high-strength metal sheets.

Stainless steel

Stainless steel

Steel

Steel

Non-ferrous metals

Non-ferrous metals

Paints/fillers

Paints/fillers

Abrasive non-woven roll with fine, flexible fibres for a good surface finish. • Flexible for optimum adjustment to the workpiece • Uniform surface finish Machine suitability: This product is sold in rolls: the abrasive can then be cut to length for use in manual grinding (shape RMA 0A). Material suitability: The VLSR non-woven abrasive has been designed especially for processing stainless steel (SST, Inox), e.g. 1.4031 (X5CrNi18-10 or 304) and steel (carbon steel – structural steel, St37, S235JR and 1.0037) and cast steels, as well as aluminium and other non-ferrous metals such as copper, brass and bronze, etc. Users will also achieve very good results with the RHODIUS VLSR non-woven abrasive when working on paint and filler. Structure and production: The non-woven abrasive features fine and extremely flexible fibres. These help to achieve a precise and very even surface finish. Quality: The RHODIUS VLSR non-woven abrasive gives users a tool that easily meets even the demanding requirements for quality in manufacturing and the skilled trades. Applications: This tool is an excellent choice for jobs that need the final surface finish to be as even as possible. The fine, flexible fibres on this tool adapt optimally to the workpiece. Dimensions: The VLSR non-woven abrasive is available in the diameters of 100 mm and 115 mm. To ensure an optimum working result and surface finish at all times, the user can select from a range of grits: coarse, medium, fine, very fine and ultra fine. Industries: A RHODIUS non-woven abrasive is the perfect tool for tackling the many kinds of applications and challenges found in car repair and servicing shops, in metalwork shops, in plant and tank construction, and for general installation work. This tool makes work easier by always offering first-class cleaning performance on rustproof and acid-proofed steels, on high-strength and high-alloy steels, on tempered steels and high-strength metal sheets, and on non-ferrous metals and painted sheet metal.

Stainless steel

Stainless steel

Steel

Steel

Paints/fillers

Paints/fillers

GFRP

GFRP

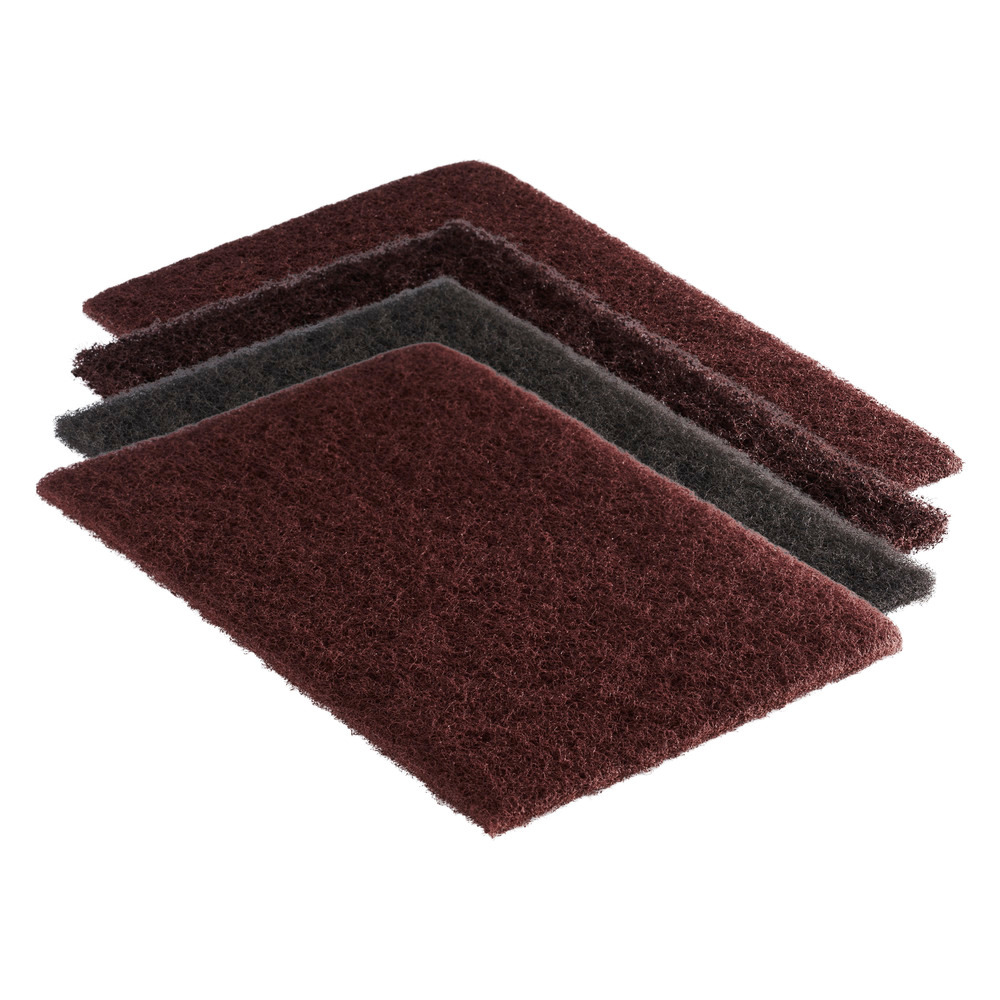

Abrasive non-woven sheets with fine, flexible fibres for a good surface finish. • Flexible for optimum adjustment to the workpiece • Uniform surface finish Machine suitability: This product is sold as pre-cut sheets of non-woven material for use in manual grinding work (shape BA 00). Material suitability: The VLS PAD non-woven abrasive has been designed especially for processing stainless steel (SST, Inox), e.g. 1.4031 (X5CrNi18-10 or 304) and steel (carbon steel – structural steel, St37, S235JR and 1.0037) and cast steels, as well as aluminium and other non-ferrous metals such as copper, brass and bronze, etc. Users will also achieve very good results with the RHODIUS VLS PAD non-woven abrasive when working on paint and filler. Structure and production: The non-woven abrasive features fine and extremely flexible fibres. These help to achieve a precise and very even surface finish. Quality: The RHODIUS VLS PAD non-woven abrasive gives users a tool that easily meets even the demanding requirements for quality in manufacturing and the skilled trades. Applications: This tool is an excellent choice for jobs that need the final surface finish to be as even as possible. The fine, flexible fibres on this tool adapt optimally to the workpiece. Dimensions: The VLS PAD non-woven abrasive is available in the dimensions of 152 mm x 229 mm. To ensure an optimum working result and surface finish at all times, the user can select from a range of grits: coarse, medium, fine, very fine and ultra fine. Industries: A RHODIUS non-woven abrasive is the perfect tool for tackling the many kinds of applications and challenges found in car repair and servicing shops, in metalwork shops, in plant and tank construction, and for general installation work. This tool makes work easier by always offering first-class cleaning performance on rustproof and acid-proofed steels, on high-strength and high-alloy steels, on tempered steels and high-strength metal sheets, and on non-ferrous metals and painted sheet metal.

Stainless steel

Stainless steel

Steel

Steel

Paints/fillers

Paints/fillers

GFRP

GFRP

Rolls with paper backing and semi-open aluminium oxide coating. • Particularly suitable for paints and varnishes • Half-open coating for non-aggressive grinding • Good for wood finishing Machine suitability: This product is sold in long rolls: the abrasive can then be cut to length for use in manual grinding. Material suitability: This high-quality RHODIUS abrasive paper has been specially designed for processing aluminium and other non-ferrous metals such as copper, brass, bronze, etc. Users will also achieve very good results with the KFPR when working on wood, paint and filler. Structure and production: The backing type used here is an A/C-weight paper. The abrasive paper is coated with aluminium oxide. The grain is semi-open coated. A long lifetime is ensured by the synthetic resin bonding. Quality: The KFPR gives users a tool that easily meets the requirements for quality in manufacturing and the skilled trades. To help make work even more cost-effective, RHODIUS rolls from the premium TOP line are recommended. Applications: The semi-open coat means that grinding work is particularly non-aggressive. Dimensions: This product is available in rolls with a length of 50 m and a width of 115 mm (shape RWA 0B). To ensure an optimum working result and surface finish at all times, the user can select from several grit levels ranging from 40 to 320. Industries: RHODIUS rolls can be cut to length as required, and are perfectly suited to tackling the many applications and challenges faced in the machine and metalwork shop, in plant construction, plumbing, interior fit-out and renovation, as well as installation work.

Non-ferrous metals

Non-ferrous metals

Wood

Wood

Paints/fillers

Paints/fillers

Waterproof abrasive paper with silicon carbide on a paper backing. • Closed coated silicon carbide for high material abrasion • Fine grinding grit 2000 • Flexible paper underlay for optimal workpiece adaptation Machine suitability: This product is sold as pre-cut sheets of abrasive paper for use in manual grinding work. Material suitability: This high-quality RHODIUS abrasive paper has been specially designed for processing stainless steel (SST, Inox), e.g. 1.4031 (X5CrNi18-10 or 304), steel (carbon steel – also termed structural steel, St37, S235JR and 1.0037) and cast steels, as well as aluminium and other non-ferrous metals such as copper, brass and bronze, etc. Users will also achieve very good results with the WSP abrasive paper when working on paint and filler. Structure and production: The backing type used here is a special waterproof A/C-weight paper. The abrasive paper is coated with silicon carbide (SiC). The grain features an exceptionally closed coating. A long lifetime is ensured by the synthetic resin bonding. Quality: The WSP gives users a tool that easily meets the demanding requirements for quality in manufacturing and the skilled trades. Applications: The flexible paper backing lets the product adapt optimally to round surfaces. Dimensions: The WSP abrasive paper is available in the size 230 mm x 280 mm. To ensure an optimum working result and surface finish at all times, the user can select from many grits, ranging from 60 to 2000. Industries: RHODIUS abrasive papers are perfectly suited to tackling the many applications and challenges faced in the machine and metalwork shop, in plant construction, plumbing, interior fit-out and renovation, as well as installation work. Not just for the pros: The WSP also provides home improvers and DIYers with a high-quality tool that ensures they can achieve superior cleaning results.

Stainless steel

Stainless steel

Steel

Steel

Paints/fillers

Paints/fillers

Non-ferrous metals

Non-ferrous metals

Abrasive paper with a paper backing and semi-open aluminium oxide coating. • Particularly suitable for paints and varnishes • Half-open coating for non-aggressive grinding • Good for wood finishing Machine suitability: This product is sold as pre-cut sheets of abrasive paper for use in manual grinding work. Material suitability: This high-quality RHODIUS abrasive paper has been specially designed for processing aluminium and other non-ferrous metals such as copper, brass, bronze, etc. Users will also achieve very good results with the KFPB abrasive paper when working on paint and filler. Structure and production: The backing type used here is a special paper. The abrasive paper is coated with aluminium oxide. The grain is semi-open coated. A long lifetime is ensured by the synthetic resin bonding. Quality: The KFPB gives users a tool that easily meets the requirements for quality in manufacturing and the skilled trades. To help make work even more cost-effective, RHODIUS abrasive papers from the premium TOP line are recommended. Applications: The semi-open coat means that grinding work is particularly non-aggressive. Dimensions: The KFPB abrasive paper is available in the size 230 mm x 280 mm. To ensure an optimum working result and surface finish at all times, the user can select from many grits, ranging from 40 to 400. Industries: RHODIUS abrasive papers are perfectly suited to tackling the many applications and challenges faced in the machine and metalwork shop, in plant construction, plumbing, interior fit-out and renovation, as well as installation work.

Non-ferrous metals

Non-ferrous metals

Wood

Wood

Paints/fillers

Paints/fillers

Tear-resistant self fastening disc with 15-hole design for processing of paints, lacquer and fillers. • Open coated, special stearate coating avoids clogging (from 180 grit) • Ideal for use together with the RH15 V backing pad • Highly tear-resistant plastic foil for long lifetime Machine suitability: The RHODIUS KSF15 V self fastening disc is designed for use with a rotary sander (shape CK 861). This creates a very high-performance tool when used with the RHODIUS RH15 V backing pad (available in 3 separate variants). Material suitability: The product has been designed especially for processing GFRP, paint and filler, as well as stainless steel (SST, Inox), e.g. 1.4031 (X5CrNi18-10 or 304), steel (carbon steel – structural steel, St37, S235JR and 1.0037) and cast steels, and also aluminium and other non-ferrous metals such as copper, brass and bronze, etc. Users will achieve very good results with the RHODIUS KSF15 V on any of the materials mentioned here. Structure and production: This disc is made from an abrasive foil and a self fastening non-woven material. The abrasive grain used here is high-performance aluminium oxide. This is open-coated and bonded with a synthetic resin. A tear-resistant plastic foil is used as the backing type here. This ensures a long tool lifetime. The stearate coating (used from grit 180) also prevents the disc from clogging and smearing. Quality: The KSF15 V self fastening disc provides users with the best RHODIUS tool in its category. RHODIUS TOPline products represent a maximum level of performance and quality. Applications: This tool is an excellent choice for jobs involving the removal of paint, varnish and filler. The 15-hole multi-perforation ensures that sanding dust is removed constantly while working. This feature improves abrasive performance while extending the tool life of a single self fastening disc. The self fastening disc also shows its strengths to the full on rustproof or acid-proofed steels, Hardox and high-strength sheet metal. Dimensions: This self-adhesive self fastening disc is available with a diameter of 150 mm. To ensure an optimum working result and surface finish at all times, the user can select from grits ranging from 80 to 2000. Industries: The KSF15 V self fastening disc is the perfect tool for the many applications and challenges faced in car repair and metalwork shops, as well as for tasks in vehicle, plant and tank construction, and installation work.

Stainless steel

Stainless steel

Steel

Steel

Non-ferrous metals

Non-ferrous metals

Paints/fillers

Paints/fillers

GFRP

GFRP