Containers and boilers need to meet a wide range of standards and requirements specifications, covering not only the insulation materials used but also the heating or cooling units and very specialised kinds of connectors. Whether your company makes acid-resistant boilers for the chemicals industry, production plant for the food industry or gas storage pressure vessels, the manufacturing process itself and the metalworking this involves means your specialists will be confronted with a wide range of challenges in their day-to-day boiler and container construction work. Here, it is important to always ensure the right tool is chosen for the material to be assembled, and for each and every work step.

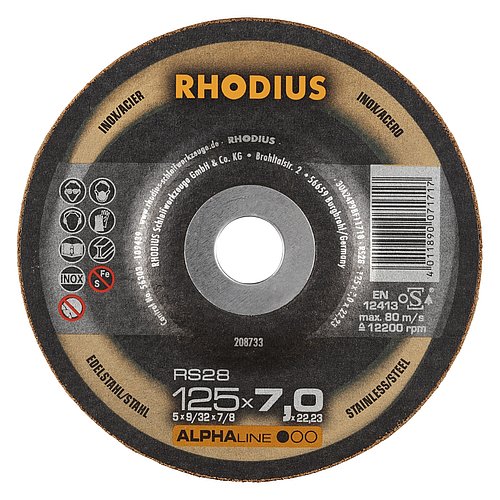

RHODIUS offers cutting discs, grinding discs and flap discs that have been specially designed for the complex and varied kinds of work steps involved in container and boiler construction. The discs offer clean, high-precision metalworking. Our application engineers and field staff know exactly which cutting disc or grinding disc is best-suited to your specific application – and which disc can offer the best cost savings when used over an extended period of time. Our advice is always on offer.