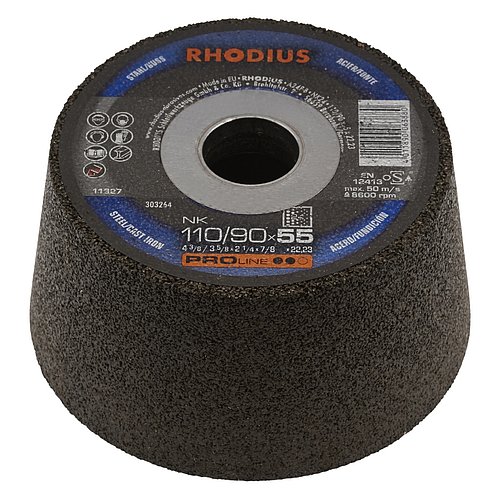

Using flap discs to reduce the costs of shipbuilding

In metal construction and especially in shipbuilding, much of the day-to-day work here is taken up with grinding processes. Specialised, industry-specific solutions are required here that offer high stock removal and long lifetimes to keep set-up times as short as possible. And if the tools used can also reduce the physical effort that operators need to apply in their work – so much the better.