It’s not always easy to notice at first glance: large cup brushes have a removable support ring. This support ring is used to stabilise the cup brush fill material. So if your work involves cleaning metal with technical brushes, the brush gives everything it has – in a controlled application onto the material. After a while, the filler wire is worn down and consumed.

But you don’t need to fit a new technical brush just yet – because this support ring can now be simply removed. This frees up new filler wire: this has the right length again and you can enjoy maximum stock removal as before. Follow this simple advice to significantly increase the lifetime of your cup brush

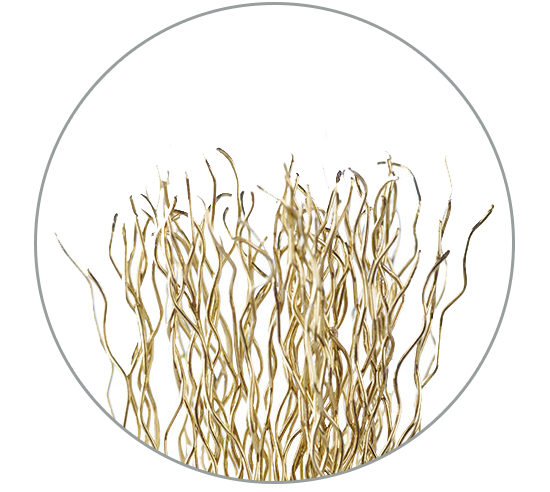

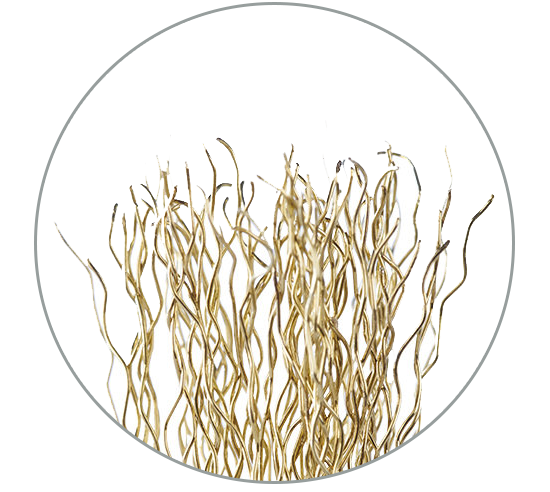

The diameter of the wire and the length of the fill material used are key factors that influence the result of the surface treatment. As a rule of thumb: The thicker the wire, the longer the lifetime of the brush. The thicker the wire, the stiffer and more aggressive the brush.

Important: Brushes fitted to handheld machines must have a maximum external diameter of 180 mm!

The fill material density depends on the number of wire tips per surface unit.

High fill material densities form the basis for optimal performance and brush lifetime, as well as ideal results from deburring work, for example. Low fill material densities increase the flexibility of the brush and are a requirement when you need to work on highly profiled surfaces.

Factors determining the contact pressure of a brush include the brush’s insertion depth in the workpiece. Triple the wire thickness is recommended, e.g. 1.0 mm insertion depth with a wire thickness of 0.35 mm. This applies in particular when deburring pipes.