Metal grinding and polishing – performance factors for an optimal finish

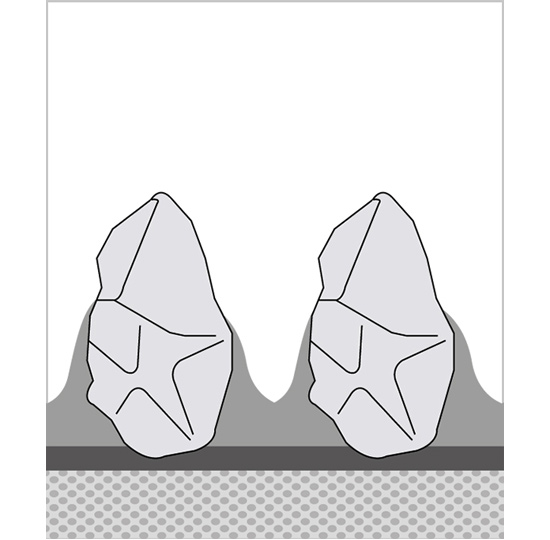

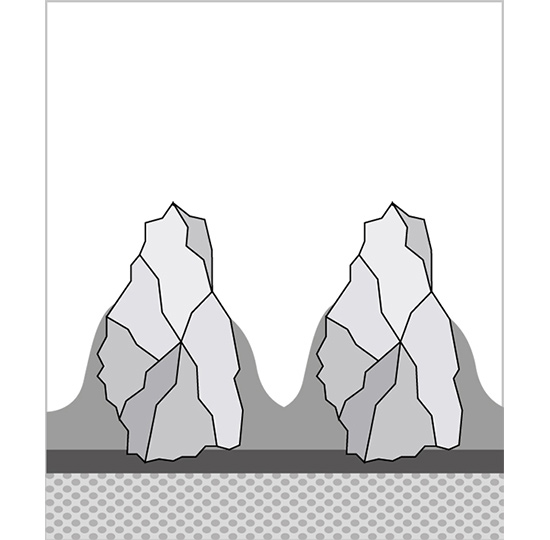

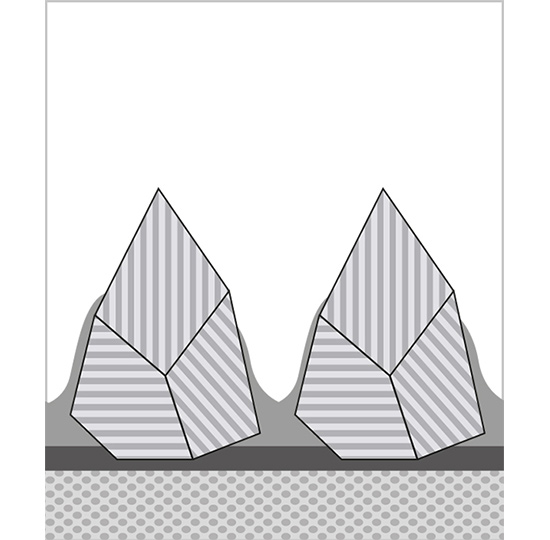

Whether you’re working with abrasive belts, rolls or sheets – anyone needing to grind or polish metal should take a closer look. With coated abrasives, there are four factors that decide on the optimum composition and therefore the best product for the application. To ensure you know what’s important when selecting the right tool, you’ll find each of these key components – backing type, bond, coating and grain – presented individually here.