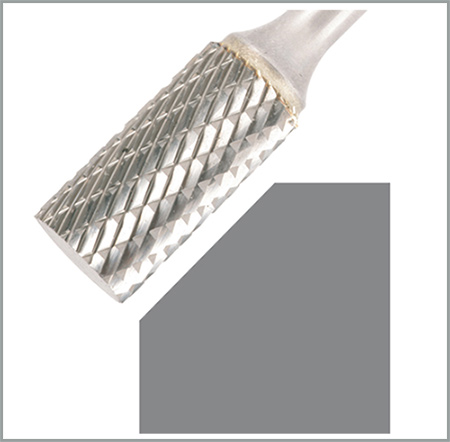

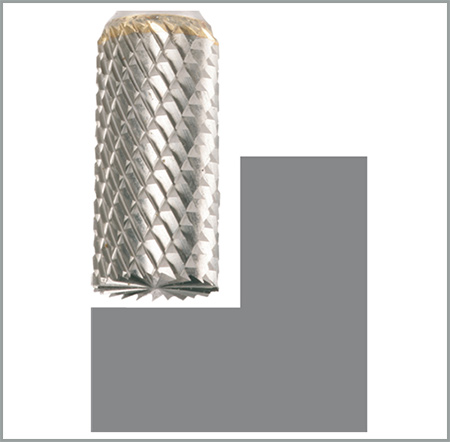

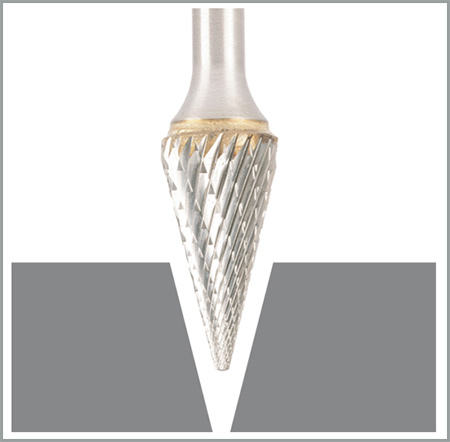

Select the right carbide burr: Shape

There’s a shape to match every job.

Do you need to work on a fillet weld, smooth out a bump or bevel off an edge? If you make sure you choose the right burr shape from the outset, you’ll get an even cleaner and faster job done on the workpiece. The figures below show which burr and which shape work the best in a range of scenarios.