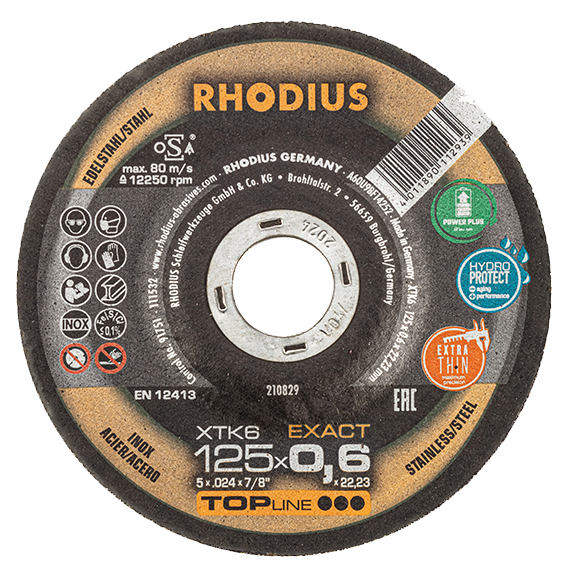

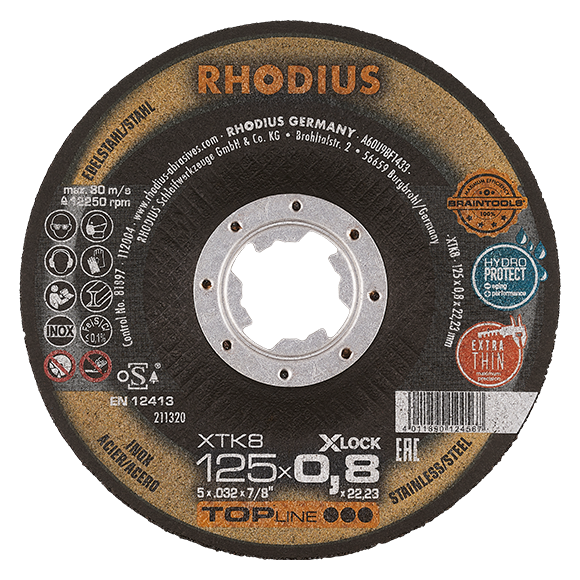

MAXIMUM PRECISION WHEN CUTTING

Our Extra-Thin technology

The processing of high-allow steels, high-strength steels or sheet metal presents users with a special set of challenges. Here, conventional cutting discs often cause considerable burr formation and undesirable tarnish colour, which results in time-consuming rework.

RHODIUS discs with Extra-Thin technology are characterised by their especially thin disc widths, offering impressive features such as outstandingly smooth operation and maximum precision while cutting with noticeably less effort required. Even with especially hard materials such as spring steels or stainless steel sheets, virtually no rework is required, thanks to the precise and cool cut.

Benefits

- Exceptionally small contact area

- Quick, cool cut

- Reduced blue discolouration

- Precise, burr-free cutting

- Less rework