Cutting and grinding with one and the same disc without changing discs – it’s a bad idea, but is unfortunately all too often the ways things are done. Although budgets have to be followed and changing discs is a pain, anyone using a standard cutting disc for rough grinding or grinding is putting their health on the line and risking serious injury. A standard, off-the-shelf cutting disc is made with just two stabilising layers of fibre glass.

This classifies the disc as a cutting disc and meets the European standard for bonded grinding tools. But this disc must not then be used to perform grinding work. The disc simply cannot take the maximum lateral load needed. The cutting disc would break due to the pressure applied and possibly explode – given the high centrifugal forces. Anyone needing to do grinding work must therefore ensure they use a real grinding disc. A grinding disc has three fabric layers. This additional fabric layer provides the extra stability needed. The disc can now take significantly higher lateral loads.

Cutting metal safely, cleanly and quickly, and grinding metal or completing small-scale deburring tasks: these are all requirements that assembly workers would ideally complete with just one disk – i.e. a combination disc that lets them get the jobs done without having to waste time changing discs. These are common tasks, after all: some metal needs to be cut, then the workpiece needs modifying or has to be prepared for a welding job. To ensure work is safe and professional here, the discs must constantly be changed over. Ideally, the installer will be using two separate machines, but this is rarely the case on-site. But if the problematic intermediate step of changing the disc could be avoided, this would make the installer’s day-to-day work much easier. Specially developed all-rounder discs that are safe to use in any application can save time and money here. And what’s more: they’re also much more user-friendly.

With the all-rounder disc RHODIUS XTK35 CROSS, three full-face fabric layers provide the necessary reinforcement and extremely high lateral stability. Thanks to a disc thickness of just 1.9 mm, the disc simultaneously offers an impressive cutting ability – even in solid material. If the angle of attack is changed from 90° to 30°, the CROSS can also be used to complete typical grinding jobs like deburring, bevelling and dressing without the need to change discs or machines, safely and simply – directly after completing cutting work. The RHODIUS XTK35 CROSS is suitable for use in steel and stainless steel applications. Removing the need to change discs saves you valuable working time.

Grinding with a clear view of the workpiece

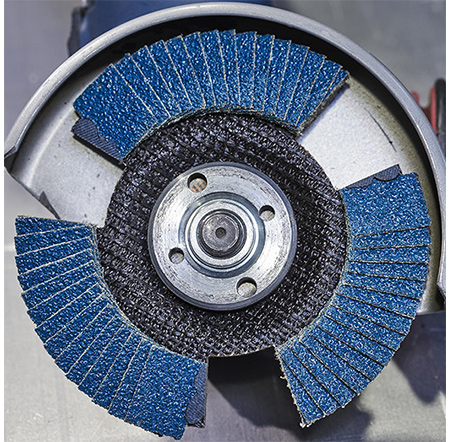

The cut-outs in the VISION series of flap discs make the discs become transparent as they rotate. This enables continuous monitoring of work results.

Wall slot chasing without middle ridge removal

Less dirt, less dust and less work – thanks to its cleverly arranged segments, the ALLCUT avoids time-consuming middle ridge removal.