MIG brazing is now a well-established joining technique in many industries. Frequently found in vehicle repair or restoration workshops, it is also now increasingly used by makers of machine enclosures and HVAC equipment. Basically, in any situation where zinc-plated or coated thin metal sheets or high-strength steel sheets need to be joined with little heat input. MIG brazing does not melt the base material: instead, a hard brazed join is created between the workpieces.

This requires perfectly matched metal sheets and keeping the gap as small as possible will make work much, much easier. Using a cutting disc no thicker than 1 mm – with 0.8 mm being even better – really simplifies the later steps in your car repair work.

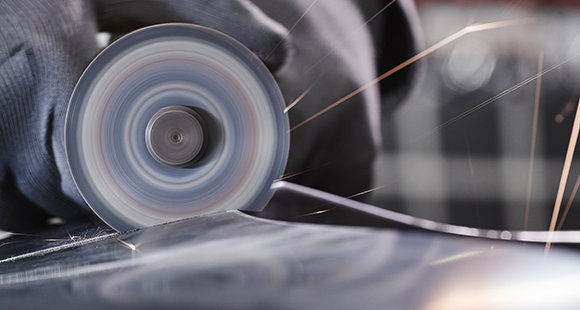

Extra-thin cutting discs from RHODIUS with 115 mm and 125 mm diameters are truly thin – ranging from 1.0 mm to an incredible 0.6 mm. These discs easily make sheet metal working – when cutting out mudguards, for example – virtually burr-free. They also have an impressively low level of sparking and an especially cool cut. And this cool cut is hugely important: it means (painted) metal sheets undergo virtually no thermal changes along the edges of the cut. Material distortion is also minimal.

A narrow, clean cut edge and high lateral stability ensure that work is precise with minimal physical effort required. There are other decisive advantages for MIG brazing. New sheets can therefore be perfectly adjusted. The brazing wire only needs to close a small gap. The gap remains narrow and distances are uniform. The superior join strength required is easily achievable.

Extra-thin cutting discs from RHODIUS in the 115 mm and 125 mm diameters are marked with the ‘XT’ product code. With a maximum disc width of 1.5 mm, they are the ideal tool for processing not just thin-walled materials but also solid materials.

Rust and paint removal

For thorough but gentle surface cleaning of body work

Coarse grinding

For the basic grinding of rough surfaces such as superstructure welding seams