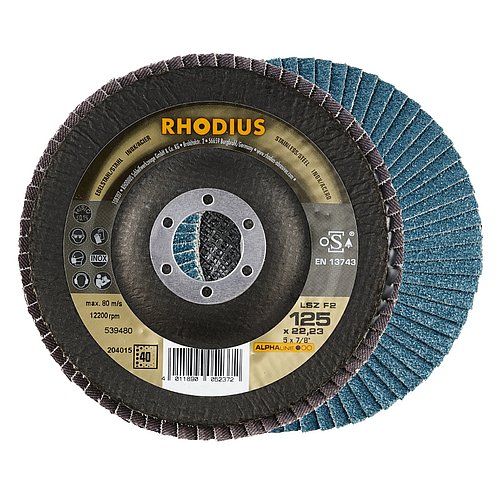

For container engineering firms, RHODIUS can offer especially aggressive grinding tools, with cutting and grinding discs that offer their users efficient, low-vibration operation.

And even where weld seams don’t need to be ground completely flat in container construction – to ensure better adhesion for paint or a powder coating, for example – deburring and grinding is still needed.

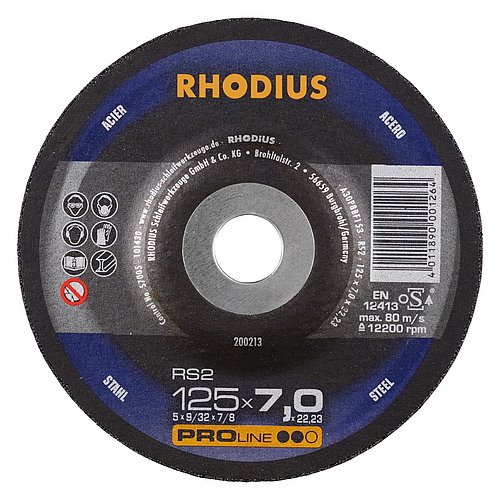

With its versatile RS2, RHODIUS has a grinding disc in its product range that offers excellent stock removal performance for grinding plus especially cost-effective working as a result of its long lifetime. Our application engineers and field staff can provide you with the best advice about the best cutting or grinding disc for container construction, perfectly matched to the material, the machine and the challenges faced by your company.