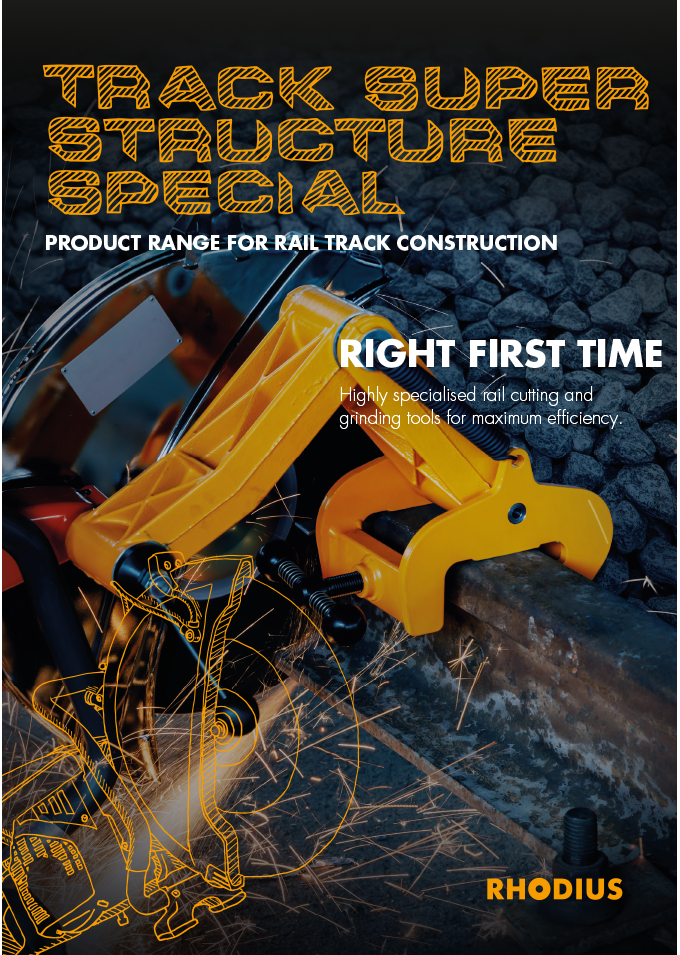

We know how to get the best results from track superstructure work

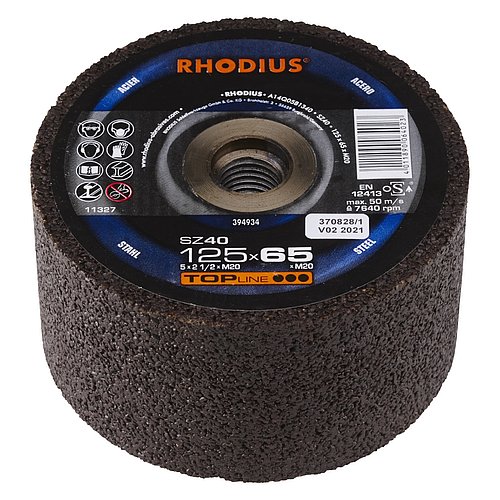

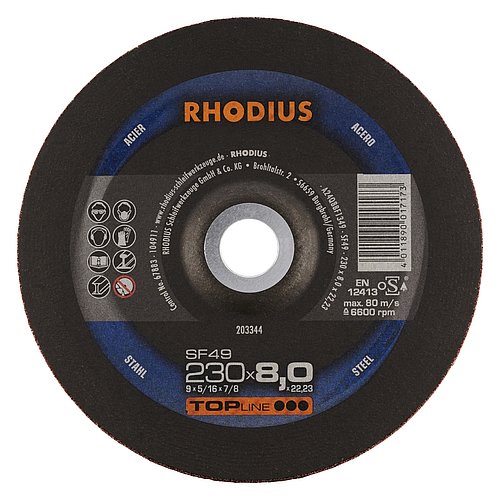

Track superstructure defects not only waste time but are also prohibitively expensive. As a partner to this sector we know what’s important, and are also well aware of how the track cutting discs, general cutting discs and grinding discs all have to be both extremely reliable while offering a maximum level of performance at all times. As in other sectors, however, work in track superstructure needs both pro-quality products and the right techniques for using them. We can provide competent support for your company’s operator training activities.