The extra-thin DG10 was specifically developed for dry cutting and offers a maximum of performance and precision on a wide range of materials. The extra-thin DG10 was specifically developed for dry cutting and offers a maximum of performance and precision on a wide range of materials. This enables extremely short cutting times and very clean cutting edges. At the same time, dust generation during dry cutting has been further reduced with the DG10. • Low dust generation • Continuous turbo rim enables high cutting speed • Narrow cut width for exact cuts and clean cutting edges • Usable for a wide range of materials • Developed for dry cutting Machine suitability: The DG10 diamond cutting disc is designed both for freehand use and for use on a stationary machine: for angle grinders and for table saws (depending on diameter). This product shows its strengths on machines in any performance class but especially when used on high-performance machines. Material suitability: The DG10 has been specifically developed for processing porcelain and ceramics as well as porcelain/glazed tiles. This high-quality RHODIUS tool is also an excellent choice for processing granite, high-fired tiles and marble. Structure and production: The DG10 features a segmented turbo rim. This offers a combination of a precise cutting edge and quick cutting times. The tool has been tested to EN 13236 and oSa, and can be used both in wet cutting and dry cutting applications. The use of a very high concentration of high-quality industrial diamonds makes the DG10 a particularly powerful tool. The disc is sintered directly. Quality: With the DG10, users get the best RHODIUS tool in its category. RHODIUS TOPline products represent a maximum level of performance and quality. Dimensions: This diamond cutting disc is available in diameters from 115 mm to 350 mm.

Tiles/ceramics

Tiles/ceramics

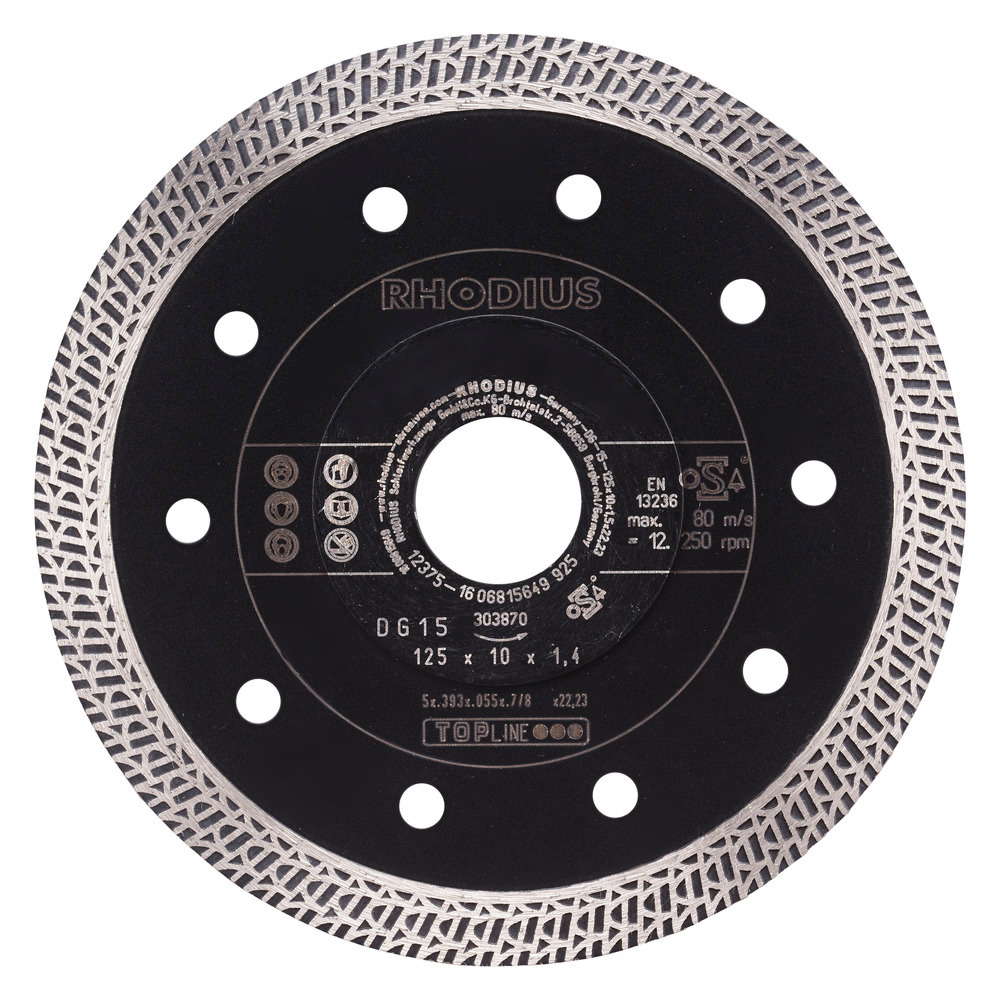

With a segment width of 1.4 mm, the DG15 is able to achieve very high cutting speeds. Due to the special diamond bond within the 10 mm high segments, it is particularly suited for cutting high-fired tiles, stoneware and ceramics. In this area, it shows its full potential and also excels with very low dust generation during dry cutting. With its reinforced steel core, the DG15 ensures a precise cut and clean cutting edges. • 10 mm high segments • Low dust generation • Optimised diamond bond for hard tiles, ceramics and fine stoneware • Reinforced steel core ensures a precise cut and a clean cutting edge • 1.4 mm segment width for a high cutting speed • Wet and dry cutting Machine suitability: The DG15 diamond cutting disc is designed for freehand use with angle grinders. This product shows its strengths on machines in any performance class but especially when used on high-performance machines. Material suitability: The DG15 has been specifically developed for processing high-fired tiles. This high-quality RHODIUS tool is also an excellent choice for processing porcelain, granite, glazed tiles and marble. Structure and production: The DG15 features a turbo rim. This offers a combination of a precise cutting edge and quick cutting times. The tool has been tested to EN 13236 and oSa, and can be used both in wet cutting and dry cutting applications. The use of a very high concentration of high-quality industrial diamonds makes the DG15 a particularly powerful tool. The disc is sintered directly. Quality: With the DG15, users get the best RHODIUS tool in its category. RHODIUS TOPline products represent a maximum level of performance and quality. Dimensions: This diamond cutting disc is available in the diameters of 115 mm and 125 mm.

Tiles/ceramics

Tiles/ceramics

The LD1 ensures a cool, fast and particularly precise cut – with a smooth continuous rim and clean cutting edge. At the same time, dust generation during dry cutting is reduced to a minimum. Suitable for wet and dry cutting. • Low dust generation • Extra-thin cutting disc for a high cutting speed and precise cuts • Smooth continuous rim for a clean cutting edge • Wet and dry cutting Machine suitability: The LD1 diamond cutting disc is designed for freehand use with angle grinders. This product shows its strengths on machines in any performance class but especially when used on high-performance machines. Material suitability: The LD1 has been specifically developed for processing porcelain and ceramics as well as porcelain tiles and marble. This high-quality RHODIUS tool is also an excellent choice for processing granite, glazed tiles and high-fired tiles. Structure and production: The LD1 features a segmented rim. This enables very high cutting speeds to be achieved while also maximising tool life. The tool has been tested to EN 13236 and oSa, and can be used both in wet cutting and dry cutting applications. The use of a very high concentration of high-quality industrial diamonds makes the LD1 a particularly powerful tool. The disc is also laser welded. Quality: With the LD1, users get the best RHODIUS tool in its category. RHODIUS TOPline products represent a maximum level of performance and quality. Dimensions: This diamond cutting disc is available in diameters from 115 mm to 230 mm.

Tiles/ceramics

Tiles/ceramics

With its 17 mm high diamond segments, the LD410 SPEED achieves an extra-long lifetime in materials from granite to concrete. The LD410 SPEED enables particularly comfortable cutting as the vibrations have been reduced to a minimum with the forged segments. In addition, the steel core has cooling openings. It is particularly suited for angle grinders, table saws and petrol-driven cut-off saws. Laser-welded. Suitable for wet and dry cutting. • Extra-long lifetime due to forged segments with a height of up to 17 mm • For angle grinders, petrol-driven cut-off saws and table saws • Special steel core with cooling openings • More comfortable cutting due to less vibrations • Wet and dry cutting • Laser-welded Machine suitability: The LD410 SPEED diamond cutting disc is designed both for freehand use and for use on a stationary machine: for angle grinders, petrol cut-off saws and table saws (depending on diameter). This product shows its strengths on machines in any performance class but especially when used on high-performance machines. Material suitability: The LD410 SPEED has been specifically designed for working on granite, marble, hard paving stones, clay roofing tiles, hard masonry bricks, reinforced concrete, ferroconcrete, concrete, paving bricks, hard stone, flagstones, concrete tubes, kerbstones, medium-hard marble shingles and concrete roofing tiles. This high-quality RHODIUS tool is also an excellent choice for processing hard concrete with aggregates, slate, hard sand-lime bricks, hard precast concrete blocks, stone blocks, sandstone and hollow stone blocks. Structure and production: The LD410 SPEED features a segmented rim. This enables very high cutting speeds to be achieved while also maximising tool life. The tool has been tested to EN 13236 and oSa, and can be used both in wet cutting and dry cutting applications. The use of a very high concentration of high-quality industrial diamonds makes the LD410 SPEED a particularly powerful tool. The disc with forged segments is also laser welded. Quality: With the LD410 SPEED, users get the best RHODIUS tool in its category. RHODIUS TOPline products represent a maximum level of performance and quality. Dimensions: This diamond cutting disc is available in diameters from 115 mm to 400 mm.

Natural stone

Natural stone

The LD200 SPEED was developed for use on light joint cutter and is especially suitable for comfortable cutting of reinforced concrete and also hard concrete with aggregates. Thanks to the forged segments, the vibrations are reduced to a minimum. The LD200 SPEED is equipped with 13mm high segments and a special steel core which is Laser-welded. Suitable for wet and dry cutting. • 13 mm segment height • For light floor saws • Special steel core with cooling openings • More comfortable cutting due to less vibrations • Wet and dry cutting • Laser-welded Machine suitability: The LD200 SPEED diamond cutting disc is designed for freehand use with a floor saw. Material suitability: The LD200 SPEED has been specifically designed for working on hard concrete with aggregates, hard paving stones, reinforced concrete, ferroconcrete, hard stone and flagstones. Structure and production: The LD200 SPEED features a segmented rim. This enables very high cutting speeds to be achieved while also maximising tool life. The tool has been tested to EN 13236 and oSa, and can be used both in wet cutting and dry cutting applications. The use of a very high concentration of high-quality industrial diamonds makes the LD200 SPEED a particularly powerful tool. The disc with forged segments is also laser welded. Quality: With the LD200 SPEED, users get the best RHODIUS tool in its category. RHODIUS TOPline products represent a maximum level of performance and quality. Dimensions: This diamond cutting disc is available in diameters from 450 mm to 600 mm.

Concrete

Concrete

The LD45 is specifically developed for use on table saws and petrol cut-off saws. Due to its high cutting speed and long lifetime, it offers impressive performance on materials ranging from hard concrete with aggregates to soft concrete blocks. The forged segments reduce the vibrations to a minimum. Suitable for wet and dry cutting. • High cutting speed • Long lifetime • Specifically for table saws and petrol cut-off saws • Wet and dry cutting • Laser-welded Machine suitability: The LD45 diamond cutting disc is designed both for freehand use and for use on a stationary machine: for petrol cut-off saws and for table saws (depending on diameter). This product shows its strengths on machines in any performance class but especially when used on high-performance machines. Material suitability: The LD45 has been specifically designed for working on hard concrete with aggregates, hard paving stones, hard masonry bricks, reinforced concrete, ferroconcrete, concrete, paving bricks, hard stone, flagstones, concrete tubes, kerbstones and medium-hard marble shingles. This high-quality RHODIUS tool is also an excellent choice for processing hard sand-lime bricks, hard precast concrete blocks, stone blocks, concrete roofing tiles and hollow stone blocks. Structure and production: The LD45 features a segmented rim. This enables very high cutting speeds to be achieved while also maximising tool life. The tool has been tested to EN 13236 and oSa, and can be used both in wet cutting and dry cutting applications. Use of high-quality industrial diamonds makes the LD45 a particularly powerful tool. The disc is also laser welded. Dimensions: This diamond cutting disc is available in diameters from 300 mm to 400 mm.

Concrete

Concrete

Optimised, slim-line geometry with brass wire for the gentle cleaning of brake calipers. • Ergonomic and non-slip handle • Gentle cleaning Machine suitability: The BSBW brake caliper brush is used for manual brush work. Material suitability: This brush has been specially designed for processing aluminium and other non-ferrous metals such as copper, brass, bronze, etc. and produces optimum working results on these materials. This brush is the ideal tool for removing stubborn brake dust and dirt on the disc brake caliper. Structure and production: The fill material used for the RHODIUS BSBW brake caliper brush is high-quality crimped steel wire. This is the fill material most commonly used for such tools, and is especially suited to light surface treatment and deburring work. The brush is particularly flexible. Quality: The hand scratch brush features an ergonomic, non-slip handle. This kind of tool can be used to achieve excellent cleaning results. The BSBW brake caliper brush gives users the best RHODIUS tool in its category. RHODIUS TOPline products represent a maximum level of performance and quality. Applications: This brake caliper brush is a very versatile tool. Users looking to achieve superior roughing, de-rusting or cleaning results will reach immediately for this hand scratch brush. This RHODIUS hand scratch brush is also an ideal choice for processing die-cast zinc, plastics and painted metal sheets as well as wood. Dimensions: The wire thickness for the BSBW is 0.30 mm. This hand scratch brush is available with 2 rows of brush wire. Industries: This makes it the ideal tool for the many applications and challenges faced in car repair and metalwork shops, in plant, container, boiler and tank construction, structural steel engineering, pipeline construction and installation work. Notice: The brush diameter, the length of brush filler as well as fill material density are all important factors that go towards producing optimum results for surface treatment. A longer wire length will make the brush softer and more flexible. These kinds of brushes will be an excellent choice for processing structured workpieces and for ensuring non-aggressive surface treatment. As wire length shortens, the brush can be used for more aggressive types of processing. To keep surface treatment work as efficient as possible, the best option here is to select the maximum brush diameter that can be fitted to the drive system on your tool. A high fill material density is not only essential for optimum performance but is also needed to ensure a long brush lifetime. In contrast, lower fill material densities increase the flexibility of the wire and are a better choice for processing profiled surfaces.

Non-ferrous metals

Non-ferrous metals

Steel hand scratch brush with straight steel wire inserts for high cleaning performance. • Great cleaning performance • To remove strong caking Machine suitability: The SHBG brush is used for manual brush work. Material suitability: This brush has been designed especially for processing steel (structural steel – also termed St37, S235JR, 1.0037 and carbon steel) and cast steels, and produces optimum results on these materials. Structure and production: The fill material used for the SHBG is high-quality straight steel wire. While this means that the brush is not particularly flexible, it makes it absolutely ideal for weld grinding work and the removal of heavy encrustations. Quality: The hand scratch brush is made from beechwood. Beech is neither too soft nor too hard, is comfortable to hold and creates a splinter-resistant handle. This kind of tool can be used to achieve excellent cleaning results. The SHBG provides users with the best RHODIUS tool in its category. RHODIUS TOPline products represent a maximum level of performance and quality. Applications: This hand scratch brush can be used anywhere. Users looking to achieve superior roughing, de-rusting or cleaning results will reach immediately for this hand scratch brush. This RHODIUS hand scratch brush for steel is the ideal choice for processing high-strength and high-alloy steels, structural steels, tool steels, tempered steels and high-strength metal sheets. Dimensions: The wire thickness for the SHBG is 0.35 mm. This hand scratch brush is available in variants with 2, 3, 4 or 5 rows of brush wire. Industries: This makes it the ideal tool for the many applications and challenges faced in car repair and metalwork shops, in plant, container, boiler and tank construction, structural steel engineering, pipeline construction and installation work. Notice: The brush diameter, the length of brush filler as well as fill material density are all important factors that go towards producing optimum results for surface treatment. A longer wire length will make the brush softer and more flexible. These kinds of brushes will be an excellent choice for processing structured workpieces and for ensuring non-aggressive surface treatment. As wire length shortens, the brush can be used for more aggressive types of processing. To keep surface treatment work as efficient as possible, the best option here is to select the maximum brush diameter that can be fitted to the drive system on your tool. A high fill material density is not only essential for optimum performance but is also needed to ensure a long brush lifetime. In contrast, lower fill material densities increase the flexibility of the wire and are a better choice for processing profiled surfaces.

Steel

Steel

Brake calliper brush: optimised, slimline geometry for cleaning steel brake callipers. • Ergonomic non-slip handle • Great cleaning performance Machine suitability: The BSBG brush is used for manual brush work. Material suitability: This brush has been designed especially for processing steel (structural steel – also termed St37, S235JR, 1.0037 and carbon steel) and cast steels, and produces optimum results on these materials. Structure and production: The fill material used for the BSBG is high-quality straight steel wire. While this means that the brush is not particularly flexible, it makes it absolutely ideal for weld grinding work and the removal of heavy encrustations. Quality: The hand scratch brush features an ergonomic, non-slip handle. This kind of tool can be used to achieve excellent cleaning results. The BSBG provides users with the best RHODIUS tool in its category. RHODIUS TOPline products represent a maximum level of performance and quality. Applications: This hand scratch brush can be used anywhere. Users looking to achieve superior roughing, de-rusting or cleaning results will reach immediately for this hand scratch brush. This RHODIUS hand scratch brush for steel is the ideal choice for processing high-strength and high-alloy steels, structural steels, tool steels, tempered steels and high-strength metal sheets. Dimensions: The wire thickness for the BSBG is 0.30 mm. This hand scratch brush is available with 2 rows of brush wire. Industries: This makes it the ideal tool for the many applications and challenges faced in car repair and metalwork shops, in plant, container, boiler and tank construction, structural steel engineering, pipeline construction and installation work. Notice: The brush diameter, the length of brush filler as well as fill material density are all important factors that go towards producing optimum results for surface treatment. A longer wire length will make the brush softer and more flexible. These kinds of brushes will be an excellent choice for processing structured workpieces and for ensuring non-aggressive surface treatment. As wire length shortens, the brush can be used for more aggressive types of processing. To keep surface treatment work as efficient as possible, the best option here is to select the maximum brush diameter that can be fitted to the drive system on your tool. A high fill material density is not only essential for optimum performance but is also needed to ensure a long brush lifetime. In contrast, lower fill material densities increase the flexibility of the wire and are a better choice for processing profiled surfaces.

Steel

Steel

Fillet weld brush with V-shaped stainless steel fill material for optimum cleaning of hard-to-reach welding seams and fillet welds. • Accurate cleaning • Great cleaning performance • Especially effective for slag Machine suitability: The SKNB brush is used for manual brush work. Material suitability: This brush has been designed especially for processing steel (structural steel – also termed St37, S235JR, 1.0037 and carbon steel) and cast steels, and produces optimum results on these materials. Structure and production: The fill material used for the SKNB is high-quality straight steel wire. While this means that the brush is not particularly flexible, it makes it absolutely ideal for weld grinding work and the removal of heavy encrustations. Quality: The hand scratch brush is made from beechwood. Beech is neither too soft nor too hard, is comfortable to hold and creates a splinter-resistant handle. This kind of tool can be used to achieve excellent cleaning results. The SKNB provides users with the best RHODIUS tool in its category. RHODIUS TOPline products represent a maximum level of performance and quality. Applications: This hand scratch brush can be used anywhere. Users looking to achieve superior roughing, de-rusting or cleaning results will reach immediately for this hand scratch brush. This RHODIUS hand scratch brush for steel is the ideal choice for processing high-strength and high-alloy steels, structural steels, tool steels, tempered steels and high-strength metal sheets. Dimensions: The wire thickness for the SKNB is 0.35 mm. This hand scratch brush is available with 3 rows of brush wire. Industries: This makes it the ideal tool for the many applications and challenges faced in car repair and metalwork shops, in plant, container, boiler and tank construction, structural steel engineering, pipeline construction and installation work. Notice: The brush diameter, the length of brush filler as well as fill material density are all important factors that go towards producing optimum results for surface treatment. A longer wire length will make the brush softer and more flexible. These kinds of brushes will be an excellent choice for processing structured workpieces and for ensuring non-aggressive surface treatment. As wire length shortens, the brush can be used for more aggressive types of processing. To keep surface treatment work as efficient as possible, the best option here is to select the maximum brush diameter that can be fitted to the drive system on your tool. A high fill material density is not only essential for optimum performance but is also needed to ensure a long brush lifetime. In contrast, lower fill material densities increase the flexibility of the wire and are a better choice for processing profiled surfaces.

Steel

Steel