Keeping pace with your metalworking

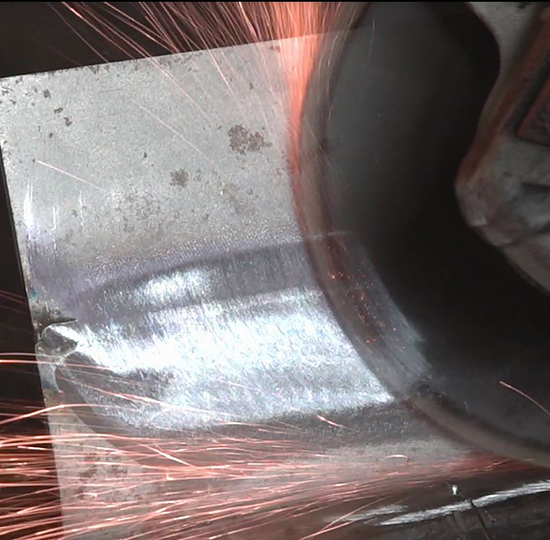

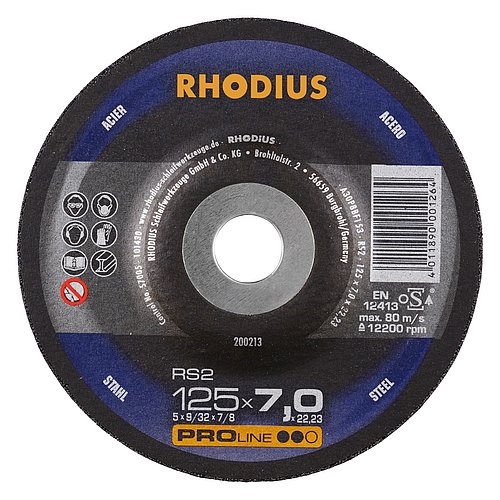

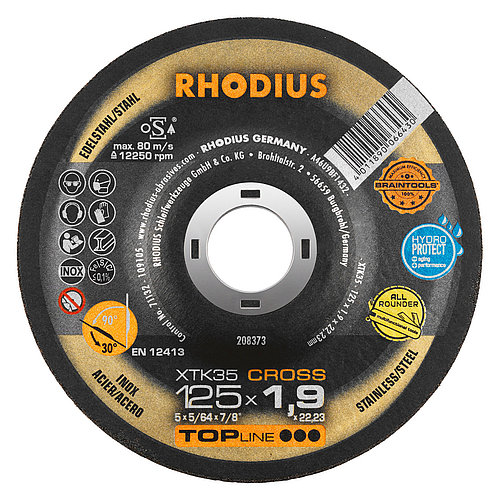

From steels and stainless steels to aluminium – plant engineering uses a wide variety of materials. The same is also true of the work processes to be completed before workpiece is finally finished. Anyone wanting optimum results from plant engineering needs to use the right grinding tools, cutting discs, rough grinding discs, carbide burrs and – for a perfect finish – the best polishing tools available. Tools for stainless steel and aluminium also have to fulfil a very particular set of criteria. Frequently, surfaces must be highly weatherproof and resistant to many materials. The risk of a particular surface rusting later on can be reduced to a minimum at the plant construction stage simply by ensuring that the right tools are used.